How can AI find black sheep machines in an industrial plant?

Even companies that are playing in the advanced league of the condition monitoring game may face the challenge of knowing which machines need to be prioritized for maintenance. For example, how can a professional responsible for the maintenance of compressors in a company realize which ones need to go to the top of priorities list?

The simple answer might be “by looking at the data collected by the sensors”, but as we have already covered in our blog post about Automatic Mode Identification (AMI) of machines, it is a difficult and time-consuming task to manually go through historic equipment vibration data.

In this blog post we are going to discuss how population-based anomaly detection is used to detect machines that have an atypical behavior, or, as we call it in MultiViz Vibration, BlackSheep Detection.

The BlackSheep Detection functionality identify assets that behave differently from the rest of the population. It is based on our Automatic Mode Identification (AMI) algorithm for multivariate time series data. The unsupervised algorithm performs multidimensional time series data segmentation and clustering, with cluster optimization to reduce model complexity to avoid overfitting/underfitting and to steer clear of sudden oscillation and transitions.

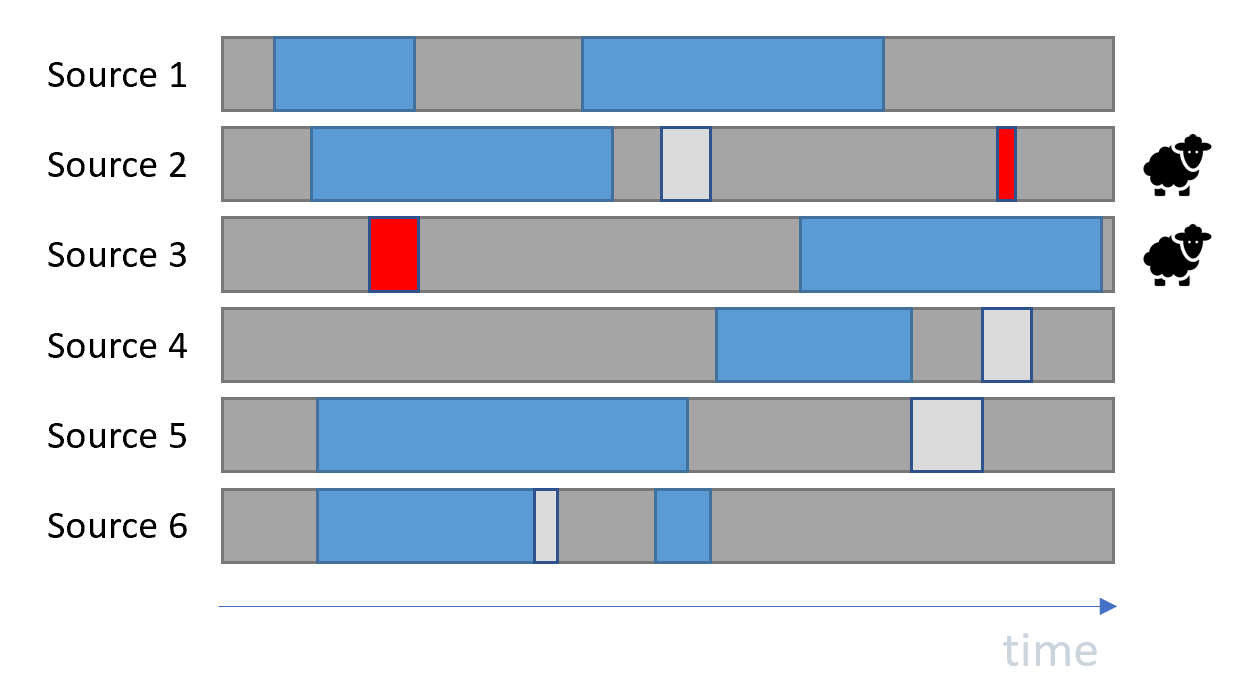

BlackSheep Detection runs mode identification over a population of assets (also called sources). Based on all modes identified in the population, the most uncommon modes will be considered atypical modes. Sources with the largest portion of uncommon modes are then labeled as atypical sources – the Black Sheep of the population.

The image below shows a population of six machines. In total, four modes are identified among all of them. The “red” mode is the most uncommon one, and the two sources which exhibit the uncommon mode are labeled as Black Sheep.

Finding Black sheeps in an industrial plant

To perform BlackSheep Detection with the MultiViz Vibration, the user simply needs to upload vibration time series data for a population of machines and request an analysis for the population of sources. This feature requires no parameters apart from a population list (sourceIds) and feature (“BlackSheep”).

The results returned by the analysis call will be a dictionary containing the list of atypical assets.

{ 'atypical_assets': ['source 2', 'source 3'] }

Going back to the example of the compressor maintenance we had in the beginning, the professional would have a list of equipment that are not behaving the way all other compressors in that plant normally do. It narrows down the examination scope from dozens of machines to just a couple, improving the efficiency of the maintenance work.

MultiViz Vibration can be accessed directly via a REST API or the va_mvg Python Package, allowing software developers or data scientists to integrate the results into an existing predictive maintenance solution or even create their own machine diagnostics service.